Blog

Navigating EMC Testing: A Helpful Primer

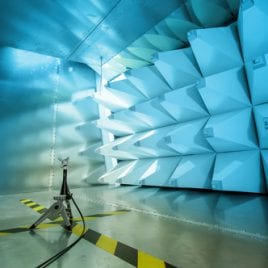

EMC (Electromagnetic Compatibility) testing is crucial for ensuring that your electronic devices can operate as intended in their electromagnetic environment without causing or being affected by electromagnetic interference. EMI (Electromagnetic Interference) occurs when an electronic device’s operation is disrupted by electromagnetic interference from an external source. The Basics of EMC Testing EMC testing is not... Read More

MIL-STD-810: Testing Standards for Robust Products

At Eurofins, we understand the Mission critical role that product testing plays in ensuring the reliability and performance of your products. That’s why we’re excited to introduce to you our MIL-STD-810 testing services, designed to help you meet the most rigorous environmental design requirements. The latest version of the standard is MIL-STD-810H Change Notice 1,... Read More

What is the UL508A Standard? Get UL 508a certification

UL 508A is the standard for the construction of Industrial Control Panels (ICPs). It provides guidelines on a variety of safety issues, such as component selection, calculation of short circuit ratings and proper wiring methods. The standard covers industrial control panel assemblies that may contain motor controllers, overload relays, fused disconnects, circuit breakers, buttons, switches,... Read More

FAQ: Wireless Coexistence Testing for Medical Devices

FAQ: Wireless Coexistence Testing for Medical Devices What wireless technology that is used in the medical device can E&E test? Eurofins E &E developed a methodology to evaluate medical devices, depending on their wireless functions (Wi-Fi, Bluetooth, ZigBee), operating up to 7.2GHz ISM bands for the following wireless technology systems: IEEE 802.11a/b/g/n/j/p Long-Term Evolution (LTE,... Read More

Eurofins E&E North America Awarded Status of PTCRB Associate Test Laboratory for RSE of 5G FR1 by CTIA Certification Authority

Eurofins E&E North America Awarded Status of PTCRB Associate Test Laboratory for RSE of 5G FR1 by CTIA Certification Authority Santa Clara Testing Facility Now PTCRB Associate Laboratory Eurofins Electrical and Electronics (E&E) North America- part of the Eurofins global network of premier testing, inspection, and certification laboratories, has been awarded the status of... Read More

Eurofins E&E North America has been Authorized by the CTIA

Eurofins E&E North America has been Authorized by the CTIA as a Test Laboratory (ATL) for the Test Plan for Wireless Device Over-the-Air Performance latest version 3.9.2 and the Test Plan for RF Performance Evaluation of Wi-Fi® Mobile Converged Devices version 2.2.1 released this month. Santa Clara Testing Facility is an Authorized Test Laboratory... Read More

Eurofins E&E Is Now An FDA ASCA-Accredited Laboratory For Medical Device Testing

On April 12th, 2021, Eurofins E&E North America, an accredited ISO/IEC 17025 test laboratory, achieved ASCA recognition by the U.S. Food and Drug Administration (FDA), for Premarket Testing of Medical Devices. Launched on September 25th, 2020, the voluntary Accreditation Scheme for Conformity Assessment (ASCA) Pilot Program was devised to enhance consistency and predictability in the... Read More

Eurofins’ Finland’s Notified Body Achieves Designation Under the New Medical Devices Regulation (EU) 2017/745

On April 7th, 2021, Eurofins Expert Services Oy (No. 0537) became a Notified Body designated under the new Medical Devices Regulation (MDR). Eurofins can now offer, to medical device manufacturers worldwide, certification services according to Regulation (EU) 2017/745 for European market access covering an extensive range of medical device technologies1. The new Medical Device Regulation... Read More

Eurofins E&E’s David Trevayne-Smith to Chair PTCRB Editorial Working Group

Eurofins E&E’s David Trevayne-Smith to Chair PTCRB Editorial Working Group Eurofins Electrical & Electronics (E&E) North America—part of the Eurofins global network of premier testing, inspection, and certification laboratories—is pleased to announce that Business Development Executive David Trevayne-Smith has been named the chair of the PTCRB Editorial Working Group. PTCRB is a certification program established... Read More

Eurofins E&E Names Justin Dean General Manager of Union City Facility

Eurofins E&E Names Justin Dean General Manager of Union City Facility October 9, 2020 (Baltimore, MD) Eurofins Electrical & Electronics (E&E) North America, part of the Eurofins global network of laboratories, has named Justin Dean as General Manager of the company’s Union City testing facility. Justin will focus on expanding capabilities and capacity for Eurofins... Read More